Design is always a multi-stage process. A lot of people might think that a designer takes an idea, hands it over to a factory for manufacture, and it’s all done. In fact, the design process is always a back-and-forth between the world of the designer’s imagination, and the world of what can actually be done. Lots of constraints affect the latter of those worlds, including the capabilities of the manufacturer, the price and weight targets of the finished product, and more. After receiving a design, the factory will provide feedback to the designer, who in turn makes changes and comes back with a revised design, and the cycle continues. Sometimes that back-and-forth is very short, sometimes it’s very long.

In the case of the Om Chair, that marriage of the imagined product and the real-world product was the most difficult of anything I have ever designed. Most of the traditional furniture vendors we approached tried to convince us that our chair was too big, and that in fact we wanted a much smaller product. So we had to educate them on why the Om Chair is larger than what they were used to seeing. Next, they would tell us that our goal of a flat-pack lightweight product was either foolish or impossible, and tried to get us to accept complete prebuilt furniture that would have made countrywide shipping impossible.

After consulting dozens of different vendors and having no success, we ended up going back to our roots in precision mechanical manufacturing. We are used to working with aerospace alloys and CNC-level precision down to 0.05mm level. In going that direction, we needed a complete rethink of the chair’s design. In the end, the final look of the chair is almost identical, but it is an entirely new creature.

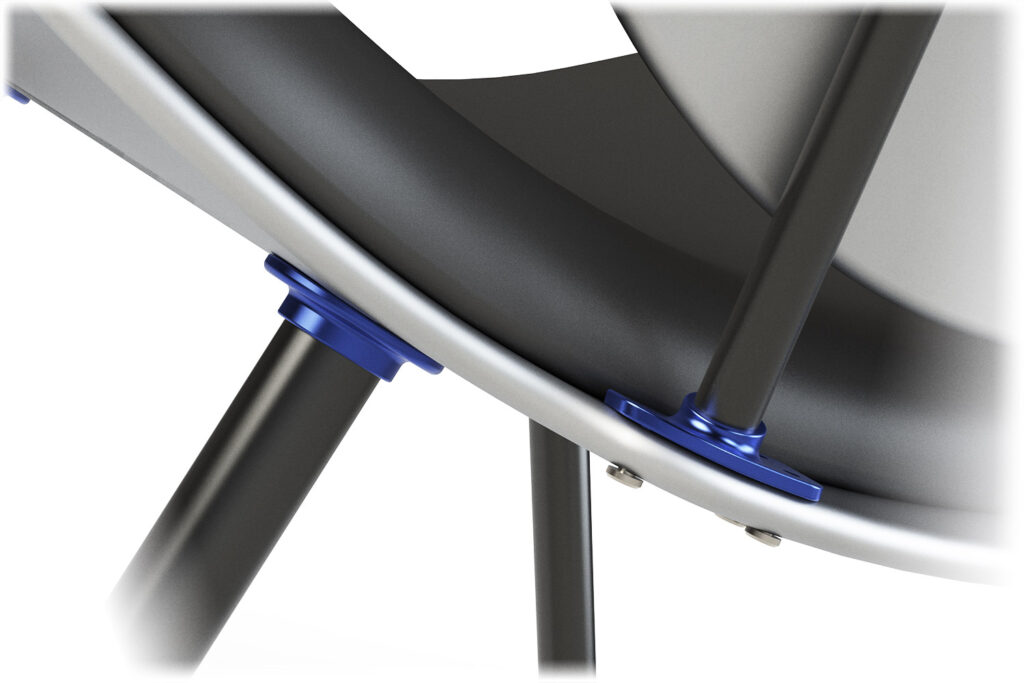

The new chair is based on precision-machined interlinks. Rather than cheap threaded inserts and stripped wood screws that you might find on your average chair, we have designed beautiful parts built to last, designed to be seen, and strong enough to last several lifetimes. This starts on the bottom of the chair, with four puck-shaped receivers, affixed by stainless steel screws which receive the chair legs. At the back of the chair, two more specialty parts bolt on to the top of the seating surface, and receive rods that support the backrest. Finally, on the backrest itself, one last piece bolts on, to receive the rods coming up from the chair.

These parts are gorgeous to look at. Each one has a unique form born entirely out of its function. Each one is CNC machined from aircraft-grade aluminum, and anodized for an exquisite appearance and exceptional corrosion resistance. There’s no cheap chromoly or ugly curtain-rod seams. Everything here is manufactured at the highest quality for an heirloom piece that will last for generations.

And we didn’t take this route just for the sake of being high tech or pretentious. This approach comes with very real benefits to every aspect of the product. First off, it’s MUCH lighter. This method saves us about 75% compared to using traditional materials. Furthermore, all of the hardware is made from sustainable materials, and is completely recyclable. Most importantly, this specialty hardware allows the chair to be packed flat, shipped anywhere on the planet, carried easily to any room, and reassembled in about one minute with no tools necessary.

We want it to be easy and convenient for everyone to experience meditation comfortably and reliably. The Om Chair is like nothing else you have ever seen, and bridges the gap between “meditation sounds neat” and “I meditate every day because it has changed my life.” The chair will become your go-to place for relaxing, resetting, and finding that calm center of life that we call the Stillside. We are in the process of commissioning our first sets of prototypes using this new construction method. Once those are in, it will be time for our official launch. We can’t wait to show this product off when it’s finally ready for prime time! Keep your eyes peeled.